A case study of root cause analysis for tackling discolouration through intelligent online monitoring.

Introduction

Akubic were approached by a UK water utility to assist them in finding out why one of their water networks was having so many customer contacts regarding discoloured water. At the beginning of the project, the water utility knew where their customer complaints were but with little idea about where the discoloured water might be coming from. This created the following heatmap of complaints:

One difficulty with discolouration is that it propagates, so where the complaints are arising may not be where the problem is starting. It is therefore key to monitor sections of pipe upstream in order to narrow down the source.

Network Monitoring

Based on the customer contacts, we proposed a total of 12 monitoring locations to identify where the source of the discolouration may be arising from, the exact number of devices is dependent of the complexity of the network.

With network monitoring, using our Intellisonde DI multi-parameter sensors, we were able to use our discolouration analysis toolbox within our Insight platform to characterise the pipes in the network as to what was causing the discolouration in each area.

This was only possible due to a number of key features about the Intellisonde DI:

With network monitoring, using our Intellisonde DI multi-parameter sensors, we were able to use our discolouration analysis toolbox within our Insight platform to characterise the pipes in the network as to what was causing the discolouration in each area.

This was only possible due to a number of key features about the Intellisonde DI:

- Highly stable and sensitive turbidity measurements, as the analysis is performed under normal conditions

- (rather than waiting for a discolouration event) we are primarily analysing variations of less than 0.05 NTU.

- Flow monitored at the same location as turbidity. The Intellisonde DI is unique in its multi-parameter data capture, this allows for the flow and turbidity to be measured together so that the characterisation can be run effectively.

- The measurement must be done in pipe. Often flow cells are used for turbidity monitoring, however they can add a lag to the measurement, invalidating the characterisation, or they cannot see the particles that get disturbed in the pipe under certain conditions – as these do not get taken up by the feed out of the pipe.

- A minimum sampling rate of 2 minutes. As the characterisation is looking for small changes, the highsampling rate ensures that there is a greater chance of capturing a small disturbance.

Characterisation

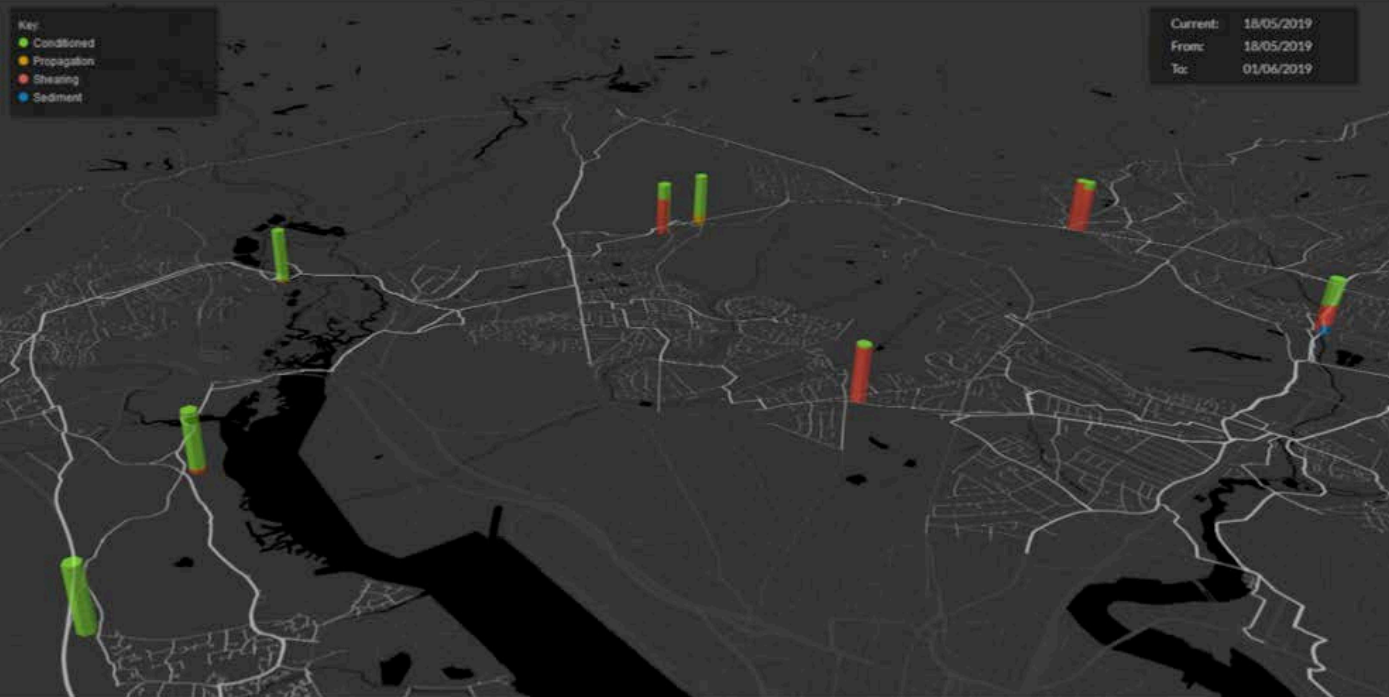

Through the analysis on our Insight platform, we are able to see this geospatially and identify the problem areas and the root cause at those places: The characterisations we are able to identify using our Insight platform with in-pipe monitoring are:

- Conditioned pipes – low risk of turbidity problems (green)

- Propagation – discolouration issues originate upstream and propagate down (orange)

- Local Shearing – discolouration issues originate locally from material shedding off of the pipe walls during times of higher flow (red)

- Sediment – Material is stirred up with any amount of flow, indicating that it is not attached to the walls, but is instead settling on the bottom of the pipe (blue)

It is clear from the geospatial analysis in Insight, that there is a ring-main structure in the network which was causing poor conditioning of the pipes. This meant that material was shearing off locally in these pipes and propagating around the ring-main. When it reached the balance point in the ring-main, it settled out and formed sediment – as can be seen by the blue portion on the right-hand side of the figure.

Root Cause and Solutions

From network monitoring we had identified that the root cause of the discolouration issues was poor conditioning of the pipes resulting in material building up on the pipe walls, which then broke off in periods of high demand or bursts. This caused large discolouration events resulting in high numbers of customer complaints. Once the root cause had been established, we investigated ways in which the pipes could be conditioned. As these were large trunk mains, flushing was not an option and would have a limited effect on the trunk main itself. Instead, we identified a transfer point to a neighbouring network that had its own water source, yet the transfer was left open.

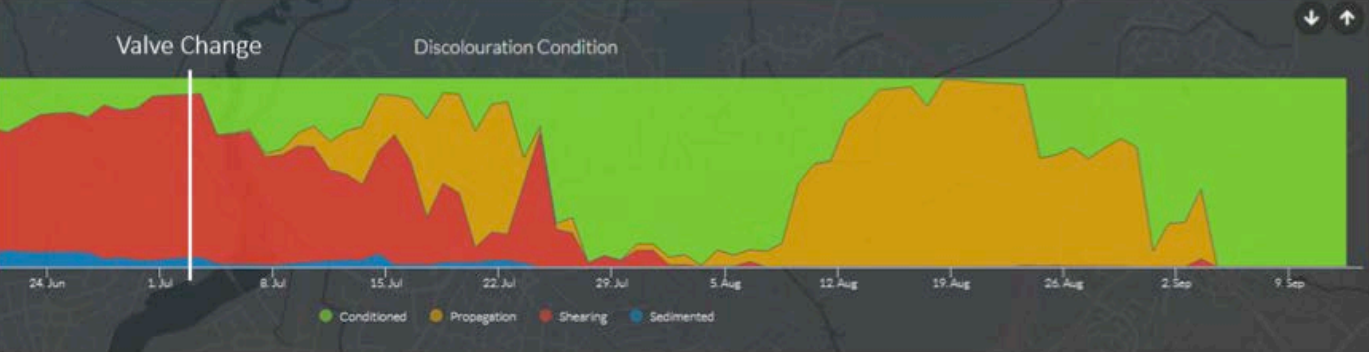

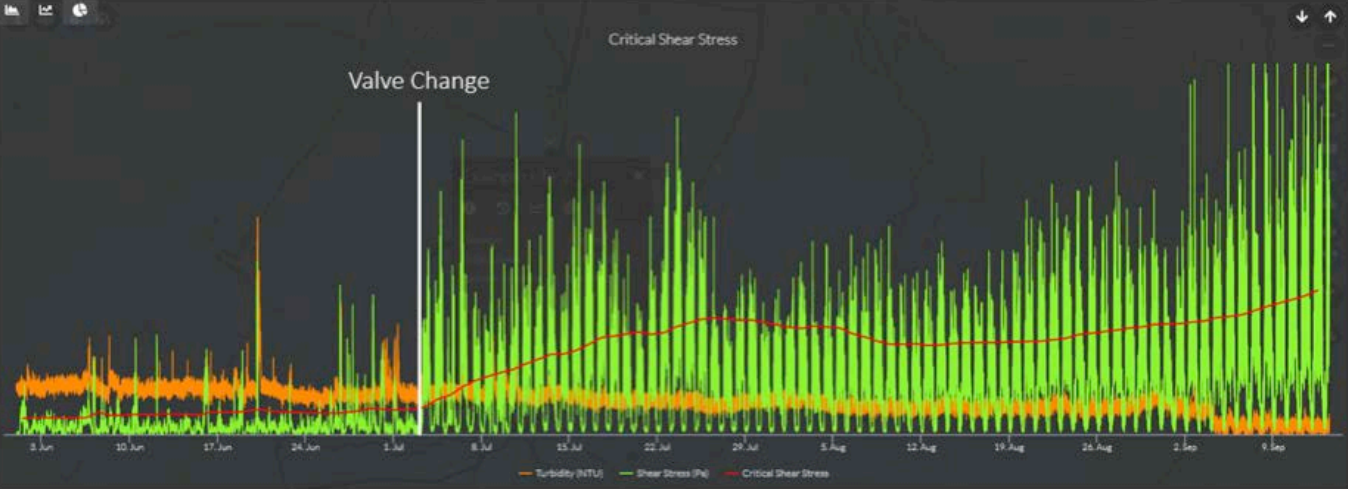

We proposed that in order to change the conditioning in the pipes, it would be possible to close this valve, thus changing the balance point in the network and conditioning the pipes that were causing the discolouration issues. This change was made and within a few weeks the pipe characterisation had showed a marked improvement which could be tracked through our Insight platform. Once the pipes had been conditioned, it would be possible to reopen the valve and return the network to its original configuration. In this way the network can be dynamically managed to condition the pipes and remove the discolouration risk.

We proposed that in order to change the conditioning in the pipes, it would be possible to close this valve, thus changing the balance point in the network and conditioning the pipes that were causing the discolouration issues. This change was made and within a few weeks the pipe characterisation had showed a marked improvement which could be tracked through our Insight platform. Once the pipes had been conditioned, it would be possible to reopen the valve and return the network to its original configuration. In this way the network can be dynamically managed to condition the pipes and remove the discolouration risk.

A complete solution from one supplier.

Start realising the benefits.